Promotional Features

Pectin Gummy Formulation: Acknowledging the Challenges and Discovering New Solutions

Across all categories, the demand for plant-based foods has risen significantly as sales, as of April 6, 2021, have peaked at around $7 billion—a 27% year-over-year increase—according to data from SPINS and The Good Food Institute. This growing consumer demand for plant-based and vegan alternatives has prompted confectioners and vitamins, minerals, and supplements (VMS) brands alike to look at how they can include these alternatives in their own formulations. Enter the gelling power of pectin.

Pectin has driven the biggest change in formulation as it grows in influence as a replacement of gelatin, an animal-derived product, in popular soft confections like gummies, marshmallows, pastilles, jellies, and chews. Between 2015 and 2020, pectin led the way in new soft confectionery product launches where a vegan or no animal ingredient claim was made; approximately 46% of new product launches in that time frame included pectin as the top ingredient. VMS brands quickly took note, and now pectin has staked its claim within the gummy supplement space.

Pectin in the VMS Market

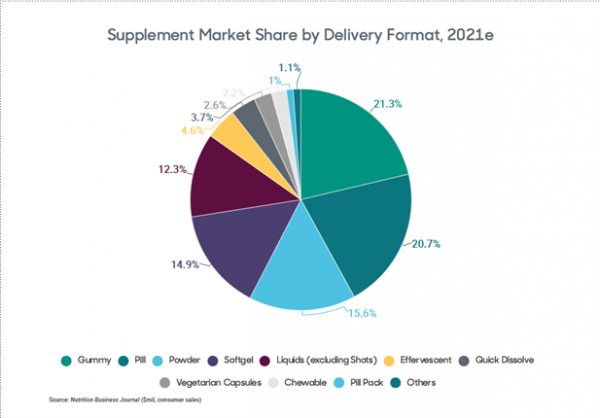

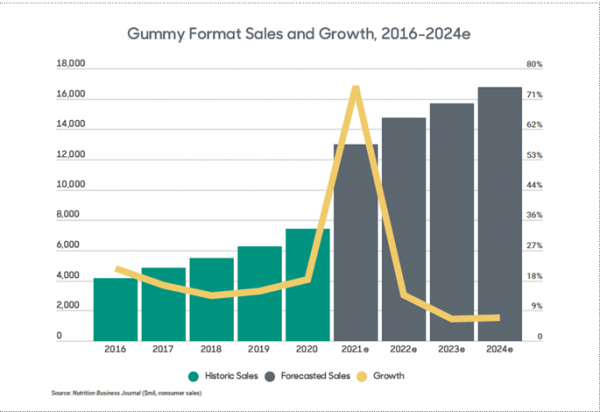

There are even more growth opportunities in the quickly expanding gummy delivery system market for VMS and those with active compounds like cannabinoids. Using gummies as a supplement delivery system is especially popular with Millennials and Gen Z consumers—who have grown up with these types of products—as well as older adults who prefer the ease of consumption over difficult to swallow and poor tasting tablets. According to a study released by the Nutrition Business Journal (NBJ), the VMS gummy market is expected to grow four times larger than it was in 2016—when it reached $4.16 billion in sales.

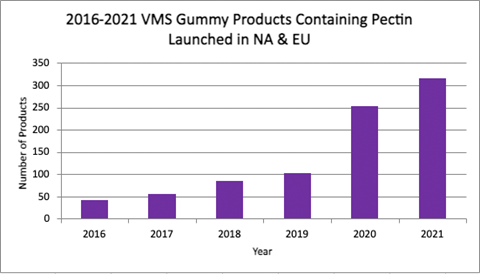

The same plant-based trends effecting change in the new confectionery product segment have carried over to new product launches in the VMS gummy market. According to a 2022 Mintel study, between 2016 and 2021, the number of new VMS gummies launched in North America and the EU containing pectin tripled. These numbers suggest that pectin will continue to displace gelatin in the foreseeable future and is on a trajectory to grow in usage within both established and emerging markets.

The Issues Working with Pectin

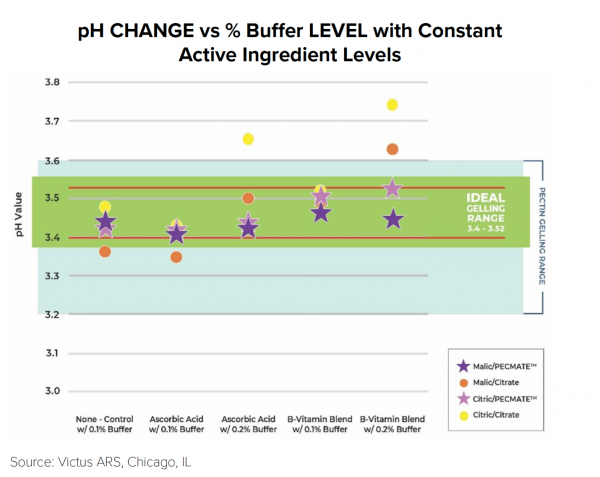

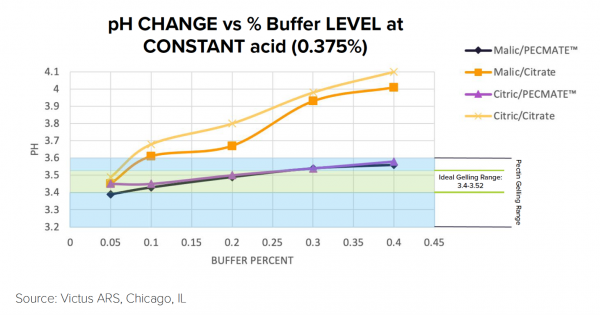

Despite this impressive growth and strong market advantage, anyone who has worked with pectin knows that it can be a perplexing ingredient for even the most seasoned brands and formulators. The challenges of working with pectin are currently managed mostly with sodium citrate–a sub-optimal buffer for pectin’s gelling range of pH 3.2 to 3.6. Additionally, introducing active compounds, flavors, and coloring agents into any system affects pH levels—especially in VMS gummies where buffer salts can be used to stabilize pH variability within the setting range. Where gelatin can be reworked if mistakes occur and it fails to properly set, pectin cannot, and inconsistent gelling in pectin can result in scrapping an entire production run. Maintaining a stable pH is not simple, and losing an entire batch is costly for manufacturers—especially when you're working with functional and active ingredients.

How Pecmate™ Pectin Enhancer Can Help

These challenges are exactly why Bartek has created Pecmate™ Pectin Enhancer: a functional ingredient designed to address well-known challenges in the production of pectin-based gummy products. VMS gummies produced using Pecmate™ held an ideal pH range (3.4 to 3.52) during production, whereas gummies formulated with sodium citrate resulted in a wider pH range (3.35 to 3.75).

These results show that using Pecmate™ is more effective than sodium citrate at reducing pH variability and results in better consistency with less scrap in production. Further, Pecmate™ provides even more advantages in formulation and manufacturing, including better product consistency, less product loss and production downtime, cleaner release from molds, and optimal buffering with any acidulant.

Using Pecmate™ in conjunction with pectin helps to reduce product loss, streamlines R&D, and contributes to an overall more consistent consumer experience from pectin-based gummy systems. Pecmate™ Pectin Enhancer is Bartek’s latest innovation to help VMS gummy brands lower production costs and capitalize on current consumer trends with speed and ease. It is the perfect partner for pectin and the best way for confectioners to save time and money.