Scientists outline more sustainable way to extract Omega-3 fatty acids from microalgae

The approach involves a direct reaction of algae oil extract with waste sulphur to produce enriched saturated triglycerides from sustainably produced algae oil.

The single-cell oils produced can form the basis for new materials suitable for nutritional supplements, animal-free meats, biodiesel, and other products.

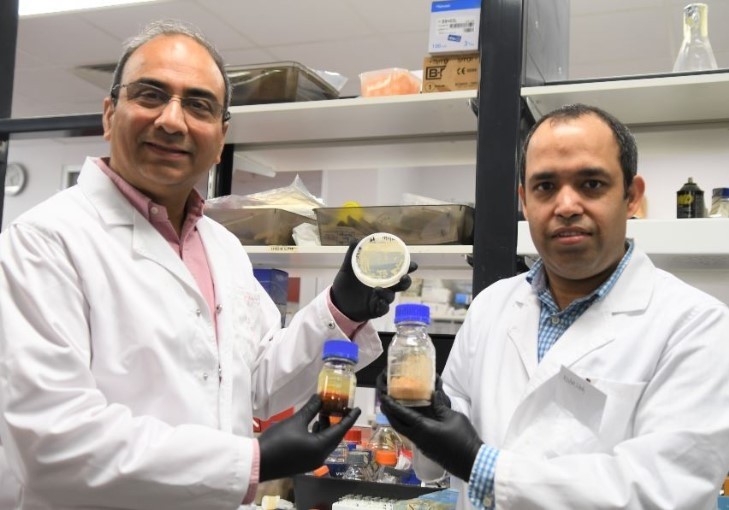

"There is growing interest in the bio-based production of lipids from algae," says Associate Professor Munish Puri, study author based at the University’s College of Medicine and Public Health.

"Single-cell thraustochytrids are especially attractive in this regard, as they can produce over 50% of their weight as triglycerides.

"But despite their promise, there remains a need for versatile downstream processing to enrich these so-called 'single-cell oils' into fatty acid classes based on degree of unsaturation. And that's what this novel approach is helping to address."

Study method

The research team began growing an in-house algae strain (Schizochytrium sp. MASA#4) to produce the biomass required for the study.

To copolymerise the algae oil with sulphur, the 409 milligrams (mg) of the oil was heated to 170 °C for five minutes turning it from a viscous orange liquid to dark brown and free-flowing liquid.

Elemental sulphur (409 mg) was added slowly over five mins to keep the mixture at approximately 170 °C.

After 30 min the viscosity increased and stirring was slowed to ensure continual mixing.

After a further 10 min at 170 °C, the flask was removed from the oil bath and allowed to cool to room temperature.

The average amount of product formed in these reactions was 458 mg of solid product and 146 mg of unreacted oil (obtained by extraction into ethanol at 50 °C).

After this process, the polymer containing oil was subjected to ethanol extraction. The ethanol in the solvent extract was removed by rotary evaporation at 50 °C, and lipid weight was determined gravimetrically.

“The algae oil reacts with sulphur” explains Professor Justin Chalker, study author and Flinders Lecturer in Synthetic Chemistry.

The polyunsaturated triglycerides form polymers with many established uses, such as environmental remediation,”

“The saturated triglycerides remain unreacted in this process, for recovery and ultimate conversion to value-added substances such as biodiesel.”

Triglyceride oil advantages

The thraustochytrid-derived triglycerides are said to offer a few advantages over plant and photoautotrophic-derived algae sources.

These include controlled fermentation, utilisation of different nutrient sources, and limited land use resulting is a more sustainable option for triglyceride production with high biomass and lipid accumulation.

Thraustochytrids can also grow on a variety of carbon sources, including glucose, glycerol, other sugars, agricultural residues, and waste products, adding to its sustainability credentials.

“Future studies will focus on upscaling the algae oil production and novel uses of the sulphur polymers reported in this study,” the team concludes.

“The upscaling will be guided by recent progress in industrial scale production of unsaturated fatty acids through fermentation, which can be adapted to Schizochytrium.

“Scaling the polymerisation process will be guided by recent reports of related polymerisations that provide hundreds of kilograms of polymer from sulphur and unsaturated triglycerides,” they add.

“With increasing interest in the synthesis and applications of sulphur-rich polymers, this study is an important step forward in the sustainable production of the triglyceride comonomer.”

Source: ACS Sustainable Chemistry & Engineering

Published online: DOI: 10.1021/acssuschemeng.1c08139

“Reaction of Sulfur and Sustainable Algae Oil for Polymer Synthesis and Enrichment of Saturated Triglycerides.”

Authors: Adarsha Gupta et al.