CRN seeks clarification on how FSMA affects ingredient suppliers that are already complying with GMPs

“We wanted to avoid any gray area, if you will,” Duffy MacKay, CRN’s vice president of scientific and regulatory affairs told NutraIngredients-USA.

The various regulations that govern the import, manufacture and sale of foods and dietary supplement ingredients and finished products in the United States were complex and, to some degree, overlapping even before the advent of FSMA. This relatively new law is the most profound change in the safety regime for foods since the advent of the Food, Drug and Cosmetic Act itself in 1937.

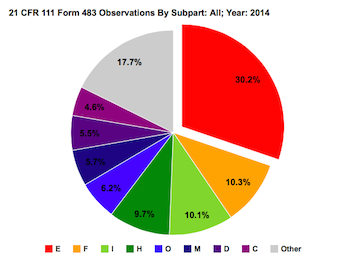

Part 111 requirements

Under Part 111, the dietary supplement GMP regulation that has been fully implemented since 2010, dietary supplement manufacturers are already (or should already) be doing many of the things specified in FSMA as far as risk-based preventive controls are concerned. And in some ways, they are adhering to a more rigid standard, as in the requirement for an adverse event reporting system.

The manufacturers of the ingredients for these products, though, did not have to comply with Part 111, being held instead to the standard in part 110, titled Current Good Manufacturing Practice in Manufacturing, Packing or Holding Human Food. Yet many dietary ingredient manufacturers have chosen for competitive, risk-mitigation or other reasons to voluntarily comply with Part 111, and therein lies the rub, according to CRN.

“While the law was being developed there was a recognition that dietary supplement GMPs already inherently had these safety elements built into them. The long and short of it is that they are more robust than the HARPC standards,” MacKay said.

Suppliers who selling bulk, unprocessed botanicals might be less inclined to go the Part 111 compliance route, MacKay said. But as a supplier goes up the value chain to more complicated extracts or premixes, that choice becomes more likely he said.

Eliminating duplication

“Also, because of the kinds of questions manufacturers are asking because of their supplier verification requirements, it just makes sense for them to have that data,” MacKay said. “The question on the table is, for those who are voluntarily complying with 111, do they now have to do a duplicative standard where they would have to comply with these new HARPC rules?”

CRN recommends therefore that the exemption for dietary supplement manufacturers be extended to ingredient suppliers that are complying with Part 111. The group further recommends that the existing requirement for biannual registration of food facilities under FSMA (the first such registrations were supposed to have been submitted in January, 2013) be slightly amended to enable it to be used as a tool to gather information on which dietary ingredient manufacturers are voluntarily complying with Part 111. In another portion of the comments, CRN says that even for those dietary ingredient manufacturers that are voluntarily complying with Part 111, the responsibility for collecting adverse event reports still should reside with the manufacturers of the finished goods.

FSMA's broad implications

In addition to the HARPC and facility registration questions, FSMA has other big potential impacts on the dietary supplement industry. The law gives FDA additional authority on recalls, which the agency most recently used to mandate a recall of the OxyElite Pro pre workout supplement manufactured by USPlabs that has been associated with cases of liver damage. And FSMA also gives FDA additional enforcement tools it can use to regulate the import of ingredients. All in all, it is a major shift in the landscape, and MacKay said companies should be rigorously informing themselves now as to how FSMA will affect their businesses, rather than to wait for the knock on the door from an inspector, as some companies seemed to have done with the rollout of the GMP requirements.

“We need to make sure that the industry is aware and active and preparing for FSMA. I think it is a really important message. Right now were are dealing with GMPs and we are seeing a lot of warning letters and all these people saying ‘we didn’t know we had to do this.’ And it’s a mess,” MacKay said.